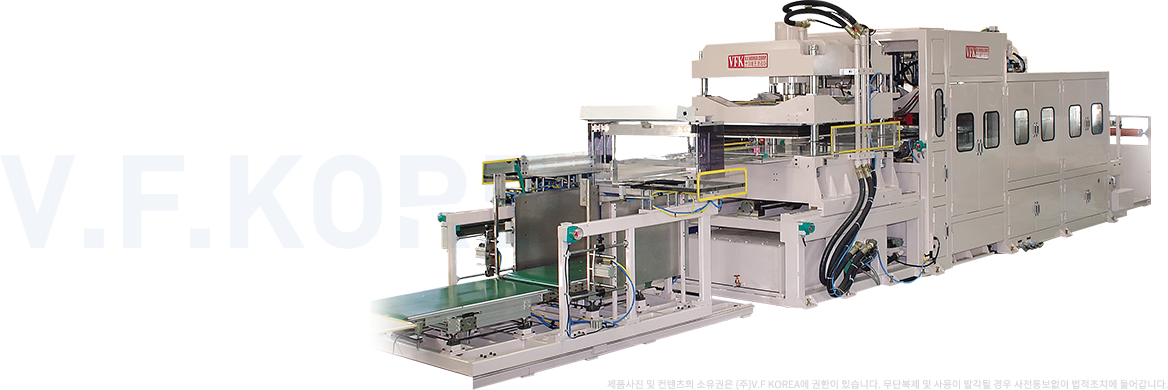

Heating method

- Feature

- Upper and Lower heating method, far infrared ceramic heater

- Heater specification

- 400 W x 122 mm x 122 mm

- Heater Box

-

1250 (W) mm X (L) 2450 mm (Maximun heating area twice that of heating area)

External emit when machine stop or an emergency using pneumatic cylinder.

- Temperature control

- ON, OFF control method by SSR (Solid state relay) and touch monitor.

- Control point

- Upper heater+ Lower heater 60 point