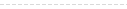

Control Panel

- PLC automatic continuation program control system

- Touch screen operation and data storage function (up to 40)

Company that trust their customers

Specifications of the equipment may be changed upon previous agreements. The price may be adjusted accordingly.

Width 1,100㎜ × Length 300㎜

1) Cutting table method using revolution of inverter motor and cam link

2) Table balance pneumatic vertical cylinder 2 sets

3) power transmission unit through crank shaft, crank arm and connecting rod

4) Precision worm gear decelerator and power transmission crank gears

5) Crank Shaft Bushing, abrasion prevention forced lubrication method

6) Connecting Rod Shaft abrasion prevention forced lubrication method

7) Table stroke: 180㎜

100 revolutions per minute (Maximum)

1) Double roller, driven by AC servomotor and material clip

2) Feed length control by digital numerical input

3) Precision worm gear decelerator

Approximately 5.0 ton

Detects forming machine's 1cycle’s signal to synchronization of interlock drive and automatic counting device.

| Description of part | Maker | Capacity | Remark |

| Cutting table drive motor | MITSUBISHI(Japan) | 11.0 ㎾ | 15 HP |

| Material feed motor | MITSUBISHI(Japan) | 1.0 ㎾ | |

| Mold height adjustment motor | SPG(Korea) | 0.75 ㎾ | |

| automatic stacking motor (conveyor) | MITSUBISHI(Japan) | 1.0 ㎾ | (Optional equipment) |

| Total | 13.8 ㎾ | 220/380Volts, 3Phase, 50/60㎐ | |